Automobile creators require the highest grades of precision in sections. A critical aspect is achieving a pristine sheen on dished ends, which can be challenging with traditional techniques. Our state-of-the-art Precision Dished EndAC Polishing Machine meets this requirement by offering an automated and precise method. This gadget applies bespoke tooling and a monitored polishing system to deliver a smooth finish on hollow finishes, maintaining optimal capability and longevity of automotive sections.

- The contraption’s programmable commands permit for precise modifications to the polishing variables, assuring homogeneity and reproducibility.

- Its compact construction enhances workspace efficiency while lowering operator weariness.

- Fusion with existing manufacturing procedures is uncomplicated, streamlining production cycles.

Next-Generation Tank Polishing Machines for Stainless Steel Fabrication

In the domain of stainless steel creation, attaining a spotless and polished surface is vital. To fulfill this task, high-efficiency tank polishing machines have emerged as necessary implements. These sophisticated machines employ cutting-edge technology to accurately excise surface imperfections and cultivate a radiant sheen on stainless steel tanks.

- What's more, high-efficiency tank polishing machines are crafted for optimal output, showing durable construction, robust motors, and modern polishing heads that eliminate surface damage.

- Hence, fabricators can maximise exceptional results with minimal effort, refining their production techniques and producing high-quality tanks that observe the stringent obligations of various branches.

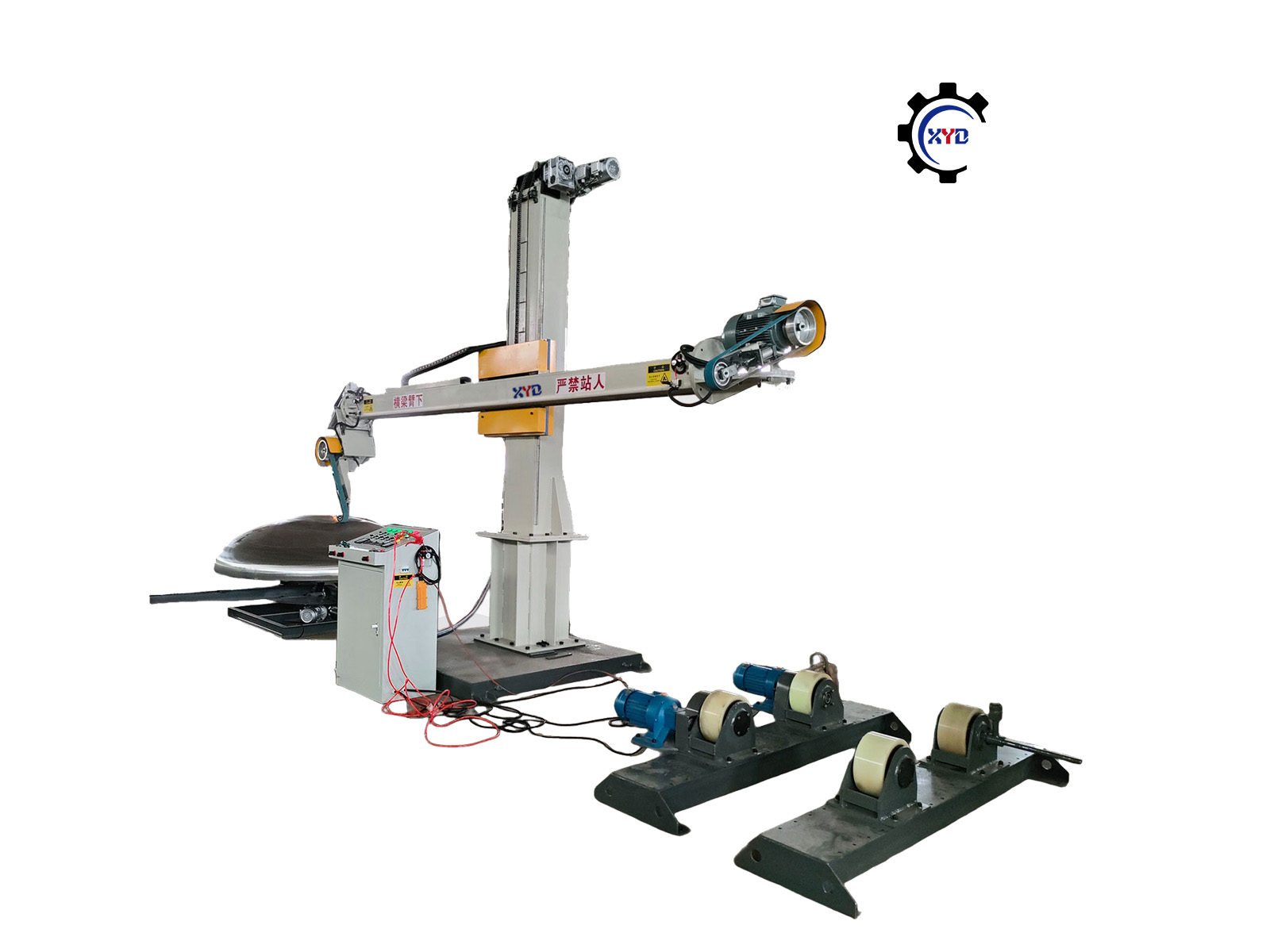

Modern Cylindrical Polishing System for Precision Engineering

The urge for exceptional surface caliber in precision engineering is constantly rising. To fulfill these rigorous demands, a original cylindrical polishing system has been formulated. This sophisticated device adopts cutting-edge strategies to produce unparalleled surface evenness. It efficiently removes imperfections and strengthens the overall functionality of cylindrical segments across a wide range of areas.

- Features include increased results, reduced manufacturing fees, and improved product stability.

- The system is developed to handle a broad range of inputs, including metals, ceramics, and plastics.

- Specialists can easily adjust the polishing standards to achieve the desired look.

This advanced cylindrical polishing system represents a significant advancement in precision engineering, equipping manufacturers to produce segments of exceptional grade and capability.

Advanced CNC Polishing Solutions for Complex Shapes

Gaining a exquisite surface on intricate units can be a arduous task. Traditional polishing techniques often struggle to yield consistent results on complex patterns, leading to time-consuming processes. However, the advent of robotic CNC polishing solutions has innovated the industry, permitting manufacturers to achieve unprecedented standards of accuracy and efficiency.

These innovative systems exploit intelligent machining technology to rigorously level surfaces with minimal operator intervention. Equipped with high-speed spindles and a variety of polishing tools, CNC machines can effortlessly handle even the most demanding shapes.

Additionally, these solutions offer optimized control over criteria such as pressure, speed, and tool path, promoting consistent results across different materials and complexities.

- Pros of automated CNC polishing include:

- Boosted precision and surface smoothness

- Decreased cycle times and production costs

- Strengthened product consistency and repeatability

- Amplified design flexibility for complex shapes

High-Performance Tank Polishing Machine for Industrial Applications

For demanding industrial areas where output is crucial, a robust tank polishing machine is an necessary tool. These machines are specifically designed to handle the rigors of repeated operation in tough environments. Equipped with durable construction and high-torque motors, they can effectively strip rust, paint, and other contaminants from tank surfaces, maintaining a smooth and sanitary finish. A variety of implements are available to accommodate different tank sizes and configurations, making them versatile for a wide range of applications.

Dished End Polishing Solution with Adaptive Control

Our modern Dished End Polisher features dynamic Adaptive Control Technology to deliver unparalleled efficiency. This process continuously regulates the polishing process in real time, ensuring optimal surface smoothness for a wide range of materials. The Adaptive Control Technology enhances the adjustment of key parameters, such as pressure, speed, and oscillation, to achieve stable results every time.

- Benefits include:

- Boosted surface finish quality

- Cut polishing time

- Superior control over the polishing process

- Elasticity for a range of materials and applications

Automated Polishing System for Precise Surface Preparation

A CNC polishing apparatus is a state-of-the-art tool used in various markets for producing high-quality surface finishes. These machines utilize computer numerical control (CNC) technology to meticulously polish surfaces, wiping out imperfections and achieving a smooth, refined appearance. The robust design of CNC polishing machines enables for flexible production.

- Engineering fields

- Synthetic materials

- Enhancing surface properties

The computer-controlled nature of CNC polishing machines delivers predictable results, curtailing human error and elevating efficiency. By harnessing a variety of accessories, these machines can manage a broad spectrum of surface kinds and items.

Large-Diameter Cylindrical Polishing Machines

Fabricating and processing large diameter cylindrical items often needs specialized equipment. These machines are constructed to reach precise surface finishes on objects with significant girth, exploiting a variety of sanding components.

The choice of cylindrical polishing equipment is strongly influenced by the specific task and desired outcome. Some common types include rotary polishers, each offering distinct advantages for creating a high gloss.

- requirements criteria demands cnc polishing machine conditions

- Securing apparatuses are essential to securely hold large diameter pieces throughout the machining process.

- Precise control of rotating speed and abrasive application are critical for producing consistent results.

Turbocharged Dished End Polishing Machine for Mass Production

In the current speedily progressing manufacturing industry, the need for productive high-volume production workflows is crucial. To meet this requirement, manufacturers are embracing cutting-edge technologies like high-speed dished end polishing machines. These high-tech equipment deliver exceptional sharpness in a time-sensitive manner, promoting consistent quality and high surface finishes for a broad range of components.

Engineered to handle large production runs with unprecedented speed, these machines employ advanced polishing techniques to attain an finish required for demanding applications. Essential features include high-speed spindles, intelligent control systems, and innovative grinding pads that work in synergy to maximize output.

Furthermore, these machines often incorporate automation capabilities for increased results and reduced labor costs. This combination of speed, accuracy, and smart technology makes high-speed dished end polishing machines a vital asset for manufacturers seeking to optimize their production processes and follow the growing calls of the market.

Accurate CNC Polishing for Aeronautical and Surgical Devices

In the high-stakes fields of aerospace and medical device production, surface quality is fundamental. CNC polishing supplies a highly accurate and solid method to produce the exacting surfaces required for these critical applications. By deploying advanced CNC machining technology, manufacturers can create surfaces with exceptional polish, accuracy, and resilience. This process empowers the production of components that observe stringent requirements for output, reliability, and trustworthiness.

- conditions expectations conditions demands preferences

- Moreover, CNC polishing elevates the corrosion resistance and biocompatibility of components used in aerospace and medical devices.

- Subsequently, it plays a vital role in extending the lifespan and enhancing the performance of these products.

Scalable Cylindrical Polishing System for Customization

Highlighting a revolutionary method to cylindrical polishing: the Modular Cylindrical Polishing System. This state-of-the-art system grants unparalleled customization, catering to your specific specifications. With its extendable design, you can conveniently adjust the polishing heads, items, and parameters to achieve the optimal finish for your cylindrical objects.

- demands expectations expectations