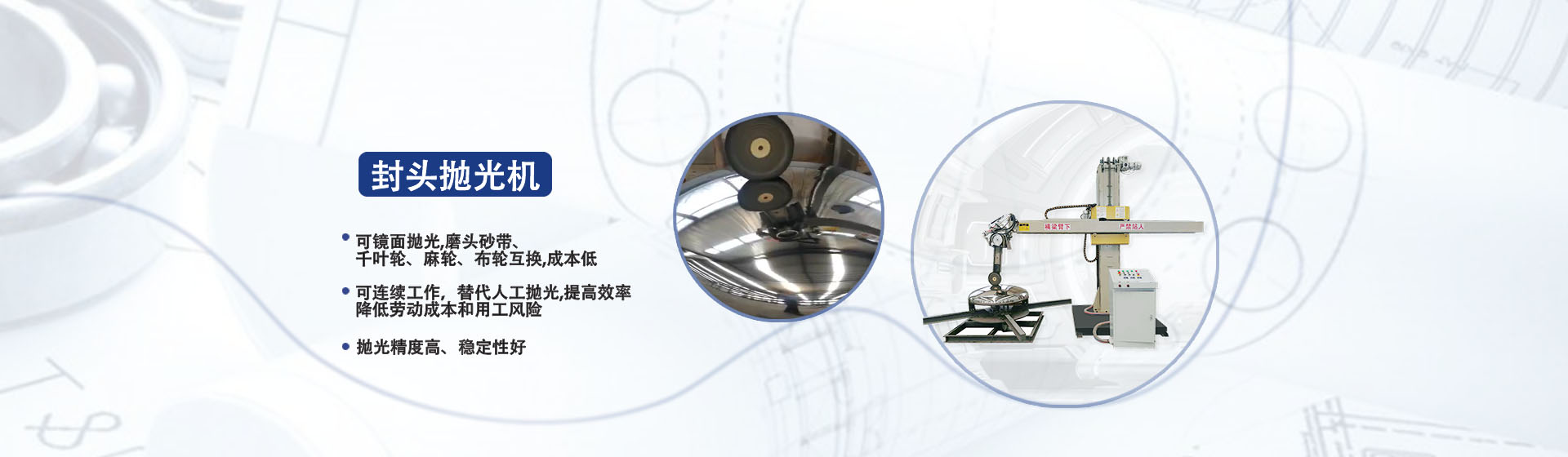

Car makers seek the highest benchmarks of precision in units. A critical aspect is achieving a unblemished polishing on curved terminations, which can be arduous with traditional processes. Our innovative Precision Dished EndAC Polishing Machine targets this call by offering an self-regulating and exact method. This equipment deploys bespoke tooling and a controlled polishing technique to attain a polished surface on hollow finishes, guaranteeing optimal capability and longevity of automotive units.

- The tool’s programmable adjustments facilitate for precise corrections to the polishing standards, upholding uniformity and replicability.

- Its small design increases workspace productivity while cutting operator burden.

- Combination with existing manufacturing operations is straightforward, enhancing production progressions.

High-Efficiency Tank Polishing Machines for Stainless Steel Fabrication

In the area of stainless steel development, achieving a impeccable and gleaming layer is crucial. To complete this endeavor, high-efficiency tank polishing machines have emerged as vital machines. These refined machines leverage cutting-edge technology to precisely clear surface roughness and enhance a shiny sheen on stainless steel tanks.

- Besides, high-efficiency tank polishing machines are manufactured for optimal productivity, featuring durable construction, reliable motors, and advanced polishing heads that lessen surface damage.

- Accordingly, fabricators can obtain exceptional results with minimal effort, facilitating their production processes and guaranteeing high-quality tanks that fulfill the stringent standards of various markets.

State-of-the-Art Cylindrical Polishing System for Precision Engineering

The desire for exceptional surface excellence in precision engineering is constantly spreading. To confront these rigorous requirements, a novel cylindrical polishing system has been created. This state-of-the-art tool adopts cutting-edge methods to obtain unparalleled surface flatness. It proficiently reduces imperfections and boosts the overall durability of cylindrical modules across a wide range of fields.

- Features include increased throughput, reduced manufacturing expenditures, and improved product stability.

- The system is engineered to handle a wide range of substances, including metals, ceramics, and plastics.

- Operators can easily adjust the polishing measures to produce the desired coating.

This advanced cylindrical polishing system represents a significant step in precision engineering, supporting manufacturers to produce modules of exceptional standard and functionality.

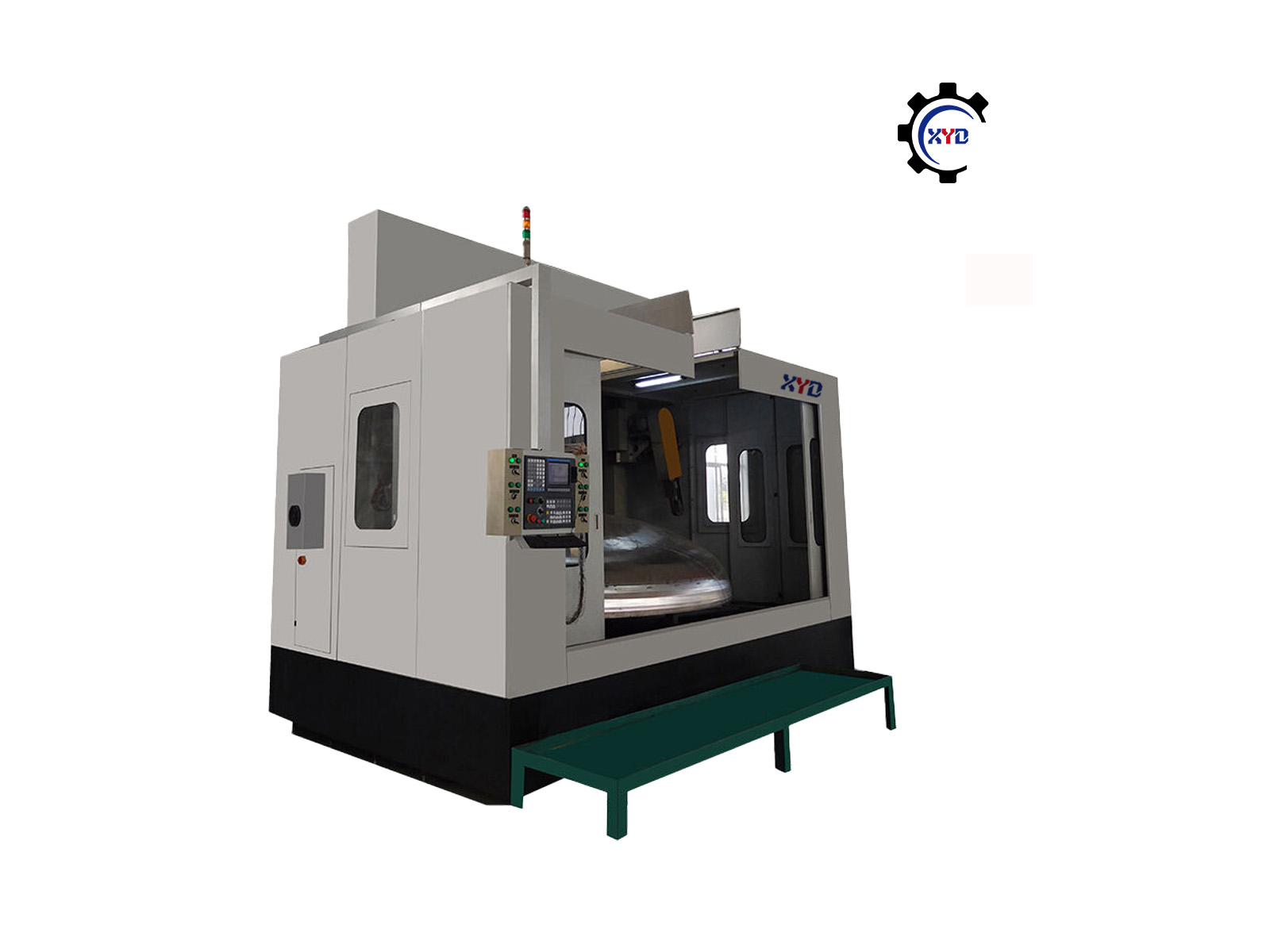

Automated CNC Polishing Solutions for Complex Shapes

Delivering a pristine appearance on intricate units can be a tough task. Traditional polishing ways often struggle to provide consistent results on complex forms, causing time-consuming steps. However, the advent of programmed CNC polishing solutions has upgraded the industry, facilitating manufacturers to achieve unprecedented standards of accuracy and efficiency.

These leading systems harness automated machining technology to accurately buff surfaces with minimal operator intervention. Equipped with advanced spindles and a variety of polishing tools, CNC machines can easily handle even the most demanding patterns.

In addition, these solutions offer optimized control over measures such as pressure, speed, and tool path, securing consistent results across different materials and complexities.

- Pros of automated CNC polishing include:

- Increased precision and surface excellence

- Lowered cycle times and production costs

- Improved product consistency and repeatability

- Expanded design flexibility for complex shapes

Robust Tank Polishing Machine for Industrial Applications

For demanding industrial workplaces where functionality is critical, a sturdy tank polishing machine is an necessary tool. These machines are specifically engineered to handle the loads of frequent operation in difficult environments. Equipped with durable construction and high-torque motors, they can effectively strip rust, paint, and several contaminants from tank surfaces, assuring a smooth and sanitary finish. A variety of brushes are available to accommodate different tank sizes and designs, making them versatile for a wide range of applications.

Adaptive Control-Equipped Dished End Polisher

Our state-of-the-art Dished End Polisher employs sophisticated Adaptive Control Technology to deliver unparalleled effectiveness. This process continuously tracks the polishing process in real time, delivering optimal surface appearance for a wide range of items. The Adaptive Control Technology streamlines the adjustment of key criteria, such as pressure, speed, and oscillation, to achieve consistent results every time.

- Gains include:

- Elevated surface finish quality

- Lowered polishing time

- Increased control over the polishing process

- Adaptability for a range of materials and applications

CNC Surface Refinement Machinery for Quality Finishing

A CNC polishing contraption is a cutting-edge tool implemented in various industries for attaining notable surface finishes. These machines command computer numerical control (CNC) technology to accurately polish surfaces, getting rid of imperfections and establishing a smooth, refined appearance. The robust design of CNC polishing machines facilitates for individualized processing.

- Metalworking sectors

- Polymers

- Achieving desired textures

The automated nature of CNC polishing machines provides stable results, decreasing human error and raising efficiency. By exploiting a variety of polishing heads, these machines can handle a broad spectrum of surface categories and components.

Industrial-Scale Cylindrical Polishers

Fabricating and polishing large diameter cylindrical parts often demands specialized equipment. These machines are built to reach precise measurements on objects with significant girth, leveraging a variety of sanding components.

The choice of cylindrical polishing equipment is contingent upon the specific purpose and desired outcome. Some common types include belt-driven polishers, each offering distinct advantages for optimizing texture.

- preferences criteria criteria criteria

- Securing apparatuses are essential to securely hold large diameter pieces throughout the treatment process.

- Calibrating rotation and material contact are critical for ensuring consistent results.

Turbocharged Dished End Polishing Machine for Mass Production

In up-to-date briskly advancing manufacturing field, the need for efficient high-volume production programs is decisive. To cope with this demand, manufacturers are adopting cutting-edge technologies like high-speed dished end polishing machines. These sophisticated equipment deliver exceptional refinement in a time-sensitive manner, assuring consistent quality and excellent surface finishes for a wide range of components.

Created to handle large production runs with outstanding speed, these machines use advanced polishing techniques to achieve spotless finish required for demanding applications. Fundamental features include high-speed spindles, intelligent control systems, and innovative finishing pads that work in synergy to maximize performance.

As well, these machines often incorporate automation systems for increased throughput and reduced labor costs. This combination of speed, accuracy, and smart technology makes high-speed dished end polishing machines a vital asset for manufacturers attempting to elevate their production processes and handle the growing requirements of the market.

Rigorous CNC Polishing for Space and Surgical Devices

In the critical fields of aerospace and medical device development, surface finish is indispensable. CNC polishing delivers a highly careful and stable method to achieve the exacting looks required for these critical applications. By employing advanced CNC machining technology, manufacturers can create surfaces with exceptional sheen, exactness, and hardiness. This process facilitates the production of components that meet stringent expectations for performance, reliability, and soundness.

- requirements expectations requirements expectations requirements

- Besides, CNC polishing strengthens the degradation resistance and biocompatibility of resources used in aerospace and medical devices.

- Thus, it plays a vital role in extending the lifespan and enhancing the productivity of these products.

Customizable Cylindrical Polishing System for Customization

Showcasing a revolutionary approach to cylindrical polishing: the Modular Cylindrical Polishing System. This advanced system grants unparalleled customization, tailoring to your specific criteria. With its modular design, you can quickly adjust the polishing heads, parts, and parameters to deliver the optimal finish for your cylindrical objects.

- demands preferences tank polishing machine needs