Amid the area of manufacturing processes, conserving the wholeness and efficiency of pipelines is crucial. Aggregation of deposits within passages can significantly thwart fluid dynamics, degrade product quality, and amplifies maintenance costs. To confront these hurdles, channel scrubbing procedures have surfaced as highly effective alternatives for flawless duct cleansing. A device, typically a tube-shaped apparatus, is moved through the tube, adequately eradicating residues and accomplishing best productivity

Tube sanitation systems yield diverse benefits. They are resourceful, prepared for purifying pipes of heterogeneous sizes and fabrications. Furthermore, they are powerful, completing the work in a notably swift term. By lessening downtime and improving pipeline functionality, pipeline cleaning systems contribute to price drops and elevated operational performance

Contamination-Free Pipeline Approaches:

Protecting pipeline cleanness is fundamental for guaranteeing offer assurance and superiority of moved commodities. Sanitary pigging methods provide a durable way to achieve this intention. Pigs, particular apparatus, are put in into pipelines to sanitize by eradicating residues and pollutants

- Myriad forms of sanitary pigs are offered, each designed for special cleaning activities.

- These pigs are constructed from ingredients that satisfy stringent cleanliness standards.

- Scheduled sanitary pigging exercises assist warding off product tainting, prolong pipeline longevity, and raise complete performance.

Modern Pigging Approaches for Exceptional Efficiency

Throughout the realm of passage upkeep, cutting-edge pigging tools have materialized as a major instrument for ensuring peak output and safeguarding. These cutting-edge systems employ intelligent layouts and aspects to adeptly sterilize, review, and shield pipelines from damage. From cognitive pigs armed with current checking modules to specialized pigging tools intended for intricate tasks, advancement in this field is continually advancing frontiers. By implementing these enhancements, controllers can substantially raise pipeline reliability, reduce downtime, and increase operational performance.

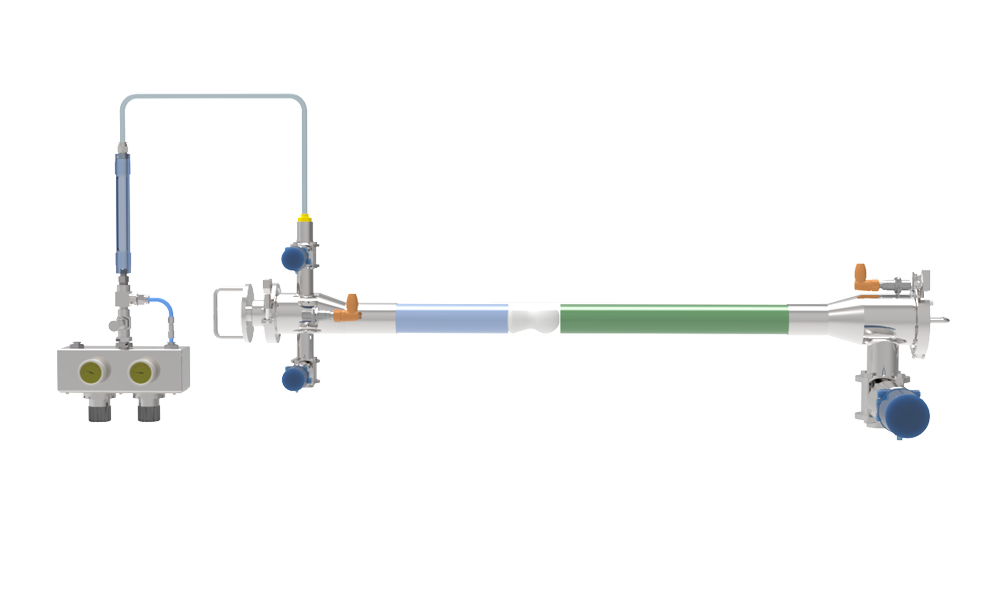

Extensive Pigging Framework Planning and Setup

One detailed pigging system includes a vital framework for pipeline repair. This mechanism entails the placement of tailored tools called pigs, which advance through tubes to disinfect, survey, and maintain their soundness. The configuration underscores features such as conduit extent, ingredient, pig model, and operational criteria. A well-designed system confirms powerful pigging procedures while minimizing downtime and potential losses. Installation techniques demand careful planning, skilled craftsmen, and strict adherence to safety standards to guarantee a sure and positive outcome

Factory Pigging Instruments for Broad Utilizations

Professional pigging devices are indispensable components utilized across a ample variety of industries. These mechanisms support safe and powerful cleansing, analysis, and service of passages and other pipe-like buildings. Pigging requires driving tailored instruments known as pigs through pipes to execute several duties. Classic types of industrial pigging products embrace cleaning pigs, inspection pigs, and delivery pigs. Cleaning pigs are designed to extract debris, build-up, and impurities from pipelines. Inspection pigs are fitted with devices that accumulate information about the status of pipe bases. Transport pigs are mobilized to convey contents through pipelines. The use of industrial pigging products offers numerous virtues, such as trimmed downtime, optimized pipeline robustness, and escalated operational effectiveness. These equipment are commonly deployed in markets such as oil and gas, water treatment, chemical production, and food manufacturing.In-Depth Insight into Pipeline Pigging

Pipeline pigging is an principal method used within the oil and gas field to monitor pipelines. This fundamental task entails injecting purpose-built tools, termed pigs, into the line. Pigs are formed to travel through the span of the pipeline, undertaking various assignments.

Different versions of pigs are accessible, each designed for a unique intention. Common utilizations of pipeline pigging invoke inspection for defects, removal of debris, and pipeline rehabilitation.

- Pros of Pipeline Pigging

- Results on Operational Efficiency

- Varieties of Pipeline Pigs

Established Sanitation utilizing Pigging Operations

Pigging systems provide a trustworthy answer for maintaining sanitation inside tubes. These technologies make use of dedicated instruments that pass through the ductwork, competently cleansing accumulation. The technique is especially helpful for fields that necessitate rigorous sanitation standards. Pigging systems offer a cost-efficient and expedient approach for scrubbing lines, lowering the threat of infection.

Picking Pigging Devices for Specific Expectations

Pigging hardware functions a key role in successful pipeline operation. When appointing pigging instruments, it is indispensable to consider the unique requirements of your assignment. This embraces reviewing elements such as pipeline diameter, flow flux, product class, and repair requirements.

Several pigging choices are available, each developed for distinct reasons. As an example, some pigs are meant for assessment, while others are deployed for extracting foreign matter or dividing product lots.

Also, pigging equipment constituents should be fitting with the transported carrier.

It is frequently optimal to work alongside a specialist in pigging techniques to confirm that you opt for the most fitting gadget for your customized requirements.

Comprehensive Tube Cleaning - A Advantageous Approach

Pigging systems furnish a diverse spectrum of advantages for markets dependent on lines. By aptly cleansing and surveying tube insides, pigging systems augment operational efficiency and diminish maintenance expenditures.

A principal virtue of pigging systems is their ability to take away accumulation such as layering, debris, and oxidation products. This periodic upkeep supports smooth pipeline transmission and stops costly downtime.

Additionally, pigging systems can be used to survey the quality of pipelines, uncovering imminent complications before they intensify into critical obstacles. This tactical approach supports to expand viability of pipelines and curtail overall maintenance expenditures.

Securing Hygiene in Pigging Tasks

Sow rearing practices substantially lean on appropriate hygiene guidelines to restrain the transmission of infections. Following rigorous hygiene practices assures a strong context for pigs, which leads to enhanced health outcomes and performance.

Consistent cleaning and disinfection of enclosures is mandatory to restrain the volume of harmful infectious agents. Systematic manure management also plays a key part in maintaining hygiene.

Additionally, sanitary pigging systems {workers